Amanda Carye stumbled on the idea for her shoe company, Idoni, when she moved to Italy for a six-month business course.

Strolling past gelato stands and chapels in Venice, she came across shops selling furlane, a slipper invented during the Second World War, when resources were scarce.

At the time, Italian shoemakers—whose craft is still passed down from generation to generation—took pride in being able to make a beautiful shoe out of pretty much anything. They used old bicycle tires to create soles with good grips, jute bags for a waterproof interior, and lush recycled fabrics like velvet curtains or silk dresses for the upper.

The result was a shoe that looked like a cross between a ballet flat and a smoking slipper, with a colorful exterior and excellent traction. “Old ladies remember wearing furlane when they were children, running around in the countryside,” Carye says. “The shoes are highly functional, but they are also very elegant.”

Carye’s shoes go for $135, rather than the usual $600 you’d expect to pay for an exclusive “made in Italy” shoe. She’s able to set a reasonable price because she only sells the shoes on her website, following the model pioneered by Warby Parker and Everlane that cuts out retailer markups.

Everyone wants products that are handmade by the most skilled artisans in the world. In turn, this model allows European artisans to find a broader audience.

According to the most recent data, released in 2014, there are more than 5,000 footwear manufacturers in Italy, employing about 77,500 workers.This means that the average factory only employs 15 people.

Shoemaking skills are often passed down from parent to child; some businesses can trace their origins back to the medieval period, when a shoemaking guild was established in Florence and transformed the trade into an art governed by rigorous rules to ensure quality.

One of the keys to these companies’ direct-to-consumer models is the idea of “post-luxury”: craftsmanship and meticulous design without the artificially inflated prices and exclusivity.

Maria Gangemi’s, founder of M Gemi, been familiar with this concept her whole life.

Growing up in Sicily, Gangemi remembers visiting boutiques that sold beautiful, high-quality shoes and bags made in local factories without massive markups.

Over the years, however, she observed that Gucci, Prada, and other luxury brands were bringing more and more business to these factories in an effort to expand their output and global footprint. In the process, they edged out smaller brands that charged less for their products. Soon, the well-crafted heels and handbags that Gangemi loved stopped appearing in local shops.

She decided to take the model she had observed as a child and modernize it by selling her products online. This way, she could sell her shoes for between $150 and $300, about a third the price of Jimmy Choos or Manolo Blahniks.

She spent months traveling around the country, talking to cobblers about the kind of shoes she wanted to make.

Some factories exclusively make leather pumps; others specialized in driving moccs. As she expanded from heels and flats into boots, sneakers, and men’s shoes, she had to find other craftsmen with a variety of different skills.

These days, her New York-based company, M.Gemi, works with a dozen family-owned factories concentrated in the Florence region.

She convinced these manufacturers to work with her by promising to order shoes throughout the year, rather than following the traditional two-season fashion calendar.

She hopes that by building long-term relationships with them, rather than just treating them like contractors, M.Gemi will be able to release a regular stream of fashion-forward shoes that are of the highest quality.

So far, M.Gemi’s approach has been working.

Business has grown four times over the last year, and half of all new customers visiting the site make a second purchase.

That’s an encouraging sign, Gangemi says, that the products are hitting the mark, quality-wise.

M.Gemi has caught the eye of investors like Accel, General Catalyst, and Forerunner Ventures, who have poured $32 million to help the company expand.

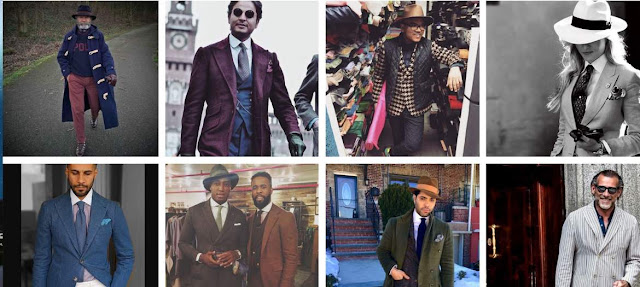

Image Credits: With thanks to

Fast Co-Design www.fastcodesign.com

M Gemi Shoes www.mgemi.com

Idoni www.idoniveneto.com

J Crew www.jcrew.com